Considering pure ammonia, chemically it is impossible for corrosion internally to a steel pipe due to lack of oxygen. However, if water is present in your liquid ammonia or oxygen present in your non-condensables you have a greater risk of internal corrosion, higher operating costs, false pressure temperature relationship, and greater SCC possibilities. There are six primary ways water can get into your ammonia system:

- It was in the existing pipe/vessel during install

- Took a bad charge of NH3 that had large concentrations of water

- Open system for maintenance

- Run operating pressure less than atmospheric

- Improper maintenance/procedures pump down into water

- Broken secondary coolant heat exchanger

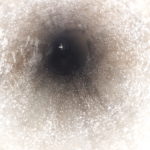

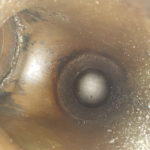

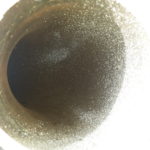

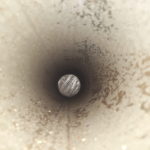

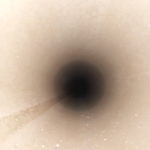

The pipes above were installed at GCAP in December of 2003 and were cut out in April of 2020 during a system upgrade. After 17 years of these pipes exposed to the conditions of an ammonia refrigeration system inside and out, you can see they are visually just as good as the day they were installed. These pipes have passed the inspection and test and we are excited to release the data. We take pride in these results and give credit to GCAP’s robust installation, maintenance, testing, and inspection protocols we have implemented in our mechanical integrity programs.

www.AmmoniaTraining.com www.ChemNEP.com www.GCAPCoolCast.com www.GCAPTraining.com