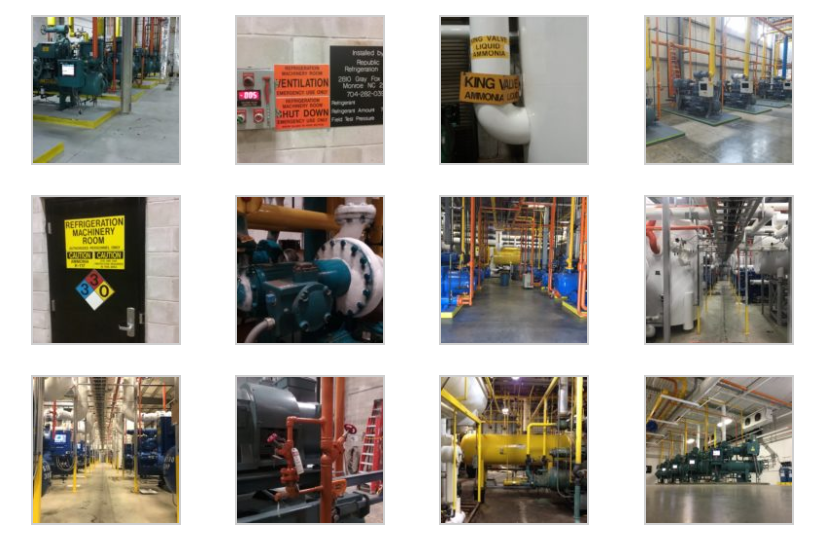

GCAP is excited to make available in 2019 a new class based on Machinery/Engine Room Design. This class is focused on the safe design of closed looped ammonia refrigeration systems. This class is well suited for an individual looking at the most relevant best practices for design and safety of the ammonia refrigeration system and the engine room that houses this equipment. The classed will be geared to folks with a background or experience in the following:

- Engineering

- Process Safety

- PSM Coordinator/Manager

- Advanced Ammonia Refrigeration Operator

- Maintenance Manager

- Refrigeration Manager

- Refrigeration Supervisor

Class Date is February 26-27, 2019 @ GCAP. Click Here To Enroll Today!!!!!!

Session 1:

- Anhydrous Ammonia Specifications

- Volume Calculations for Determining Concentration of Ammonia Release

- Use of Ammonia with Secondary Coolants

- System Design Pressure

- System Design Temperature

- Materials of Construction

- Purging

- Oil Management

- Insulation

- Foundations

- Piping

- Tubing

- Equipment Supports

- Service Provisions

- Testing

- Signage

- Labels

- Pipe Marking

- Wind Indicators

- Emergency Shutdown Documentation

- Equipment Enclosures

- General Safety Requirements

Session 2

- Machinery Room Construction

- Machinery Room Access and Egress

- Machinery Room and Combustible Materials

- Machinery Room Open Flames and Hot Surfaces

- Machinery Room Piping

- Machinery Room Eyewash/Safety Shower

- Machinery Room Electrical Safety

- Machinery Room Drains

- Machinery Room Entrances and Exits

- Machinery Room Lighting

- Machinery Room Emergency Control Switches

- Machinery Room Ammonia Detection

- Machinery Room Ammonia Alarms

- Machinery Room Ventilation

- Machinery Room Signage

- Requirements of Non-Machinery Room Spaces

Session 3

- Compressors

- Design

- Procedures

- Testing

- Equipment Identification

- Installation

- Pumps

- Design

- Procedures

- Testing

- Equipment Identification

- Installation

- Ammonia Removal

- Condensers

- Design

- Air Cooled

- Evaporative

- Shell and Tube

- Plate

- Double Pipe

- Design

- Evaporators

- Design

- Forced Air

- Shell and Tube

- Plate

- Scraped

- Jacketed Vessels

- Design

- Pressure Vessels

- Design

- Procedures

- Testing

- Identification

- Nameplate

- Installation Considerations

- Piping

- Design

- Pipe

- Tubing

- Fittings

- Flanges

- Valves

- Strainers

- Hangers

- Supports

- Isolation

- Location of Piping

- Design

Session 4

- Overpressure Protection

- Pressure Relief Devices

- Pressure Relief Protection

- Pressure Relief Piping

- Pressure Relief Discharge

- Hydro-static Over pressure Protection

Session 5

- Instrumentation and Controls

- General

- Level Indicators

- Electric Sensors

- Pneumatic Sensors

- Ammonia Detection and Alarm

- Power for Detection and Alarm

- Testing

- Detector Placement

- Alarms

- Signage

- Detection and Alarm Levels

Class Date is February 26-27, 2019 @ GCAP. Click Here To Enroll Today!!!!!!

620.271.0037