In this article you will find the advantages of training using hands-on equipment verses classroom seminar structure only. We find that some of the best training an individual can receive is specifically right off of their own equipment in their facility based upon plant’s specific standard operating procedures. On the other hand, learning the overview or theory of the application will be best suited in a training atmosphere incorporating classroom, visual aids, training props, training cut-aways, and hands on demonstration with live training equipment.

GCAP offers the majority of their classes incorporating hands-on training with live equipment and classroom structure at our facility in Garden City, KS. GCAP was established and our reputation globally is based upon hands-on training. Our facility is specifically designed with over 50,000 square feet dedicated to industrial training. This includes 3 different refrigeration engine rooms with associated equipment, 2 different boiler rooms and associated equipment. Most every industrial design from the last 4 decades and future generation application are implemented at GCAP to enhance the learning to operators, mechanics, safety personnel, and managers. Mechanics and operators do not learn solely by reading from a book, so hands on training is essential to retention and understanding. Very similar to the medical field, these individuals will enhance their understanding with both classroom and live training. GCAP’s facility is designed for that live training. Some of the benefits of sending individuals to GCAP using our facility would be;

- Live training off of live equipment

- Opportunity to demonstrate consequence of deviation with training equipment

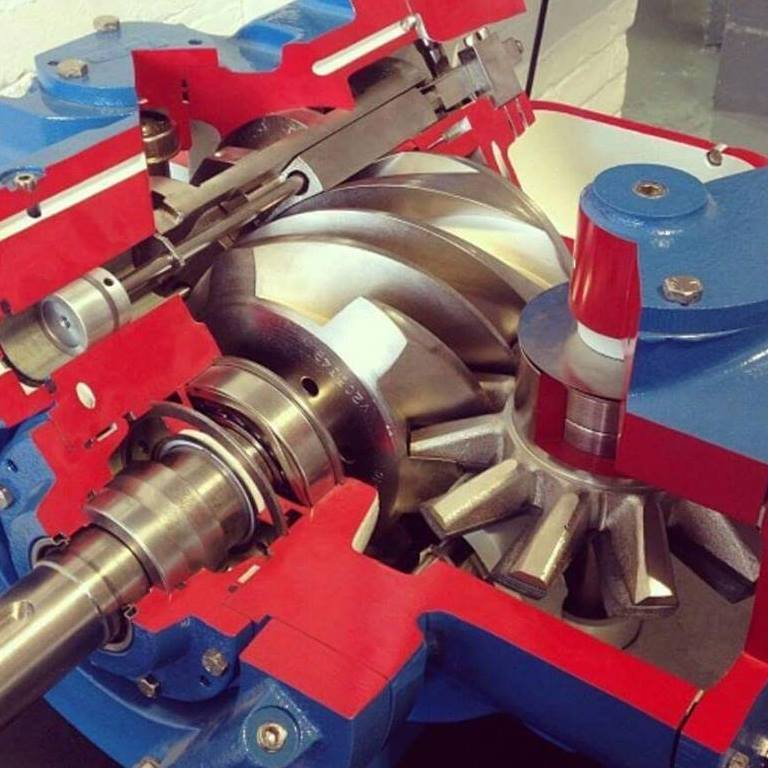

- See inside the industrial systems with glass port views and strategic sight glasses on almost every fundamental pipe in industrial applications.

- Higher test score and greater retention rate of material presented

- Easier to relate to training concepts in classroom with associated cut-aways and displays at GCAP’s facility.

- The student gets to focus on the class for the entire time they are taking the class. They would not be called out due to needs of their facility being at their facility.

- The student gets to see/touch all the cut-aways at GCAP to enhance the machines in the training labs and what they use back at their facility.

- The students get to actually operate the systems as a whole and each associated independent component as needed based upon the training scenarios such as startups, shutdowns, etc.…

People whom benefit at GCAP’s facility the most, for the first level associated classes would be individuals whom have less than 3 years of experience in their work duties for the class that they are sitting for. Individuals whom have much field experience and lack the educational credentials to match their operating knowledge seem to do well in both training at GCAP’s live facility or in seminar based classes that GCAP hosts across the nation. The following are some advantages for a company that GCAP calls “onsite training” that is not at our facility in Kansas;

- Lower investment costs in trainee for the same credential training class.

o Do not have any associated costs for travel, room, and board if the trainee gets to go home each night.

- Material presented in a slight slower pace compared to the same presentation at GCAP’s facility.

- Walkthrough of an engine room to visually look at running equipment and walk out some of the fundamental pipes.

o If facility could incorporate startup and shutdowns of their actual equipment would be beneficial to trainee as well

There are also several classes taught through GCAP that hands-on training is not required for that particular class competencies. The classes that are not built around the hands-on portion would be government regulation classes such as PSM/RMP and best practices courses such as RAGAGEP. We encourage companies investing in training to get the best out of their investment. Ultimately your decision will be the best decision for your company and thank you for choosing GCAP in the past and we hope that you will consider us for any training needs you many have in the future.

www.AmmoniaTraining.com www.BoilerLicense.com