Both OSHA and EPA through the PSM and RMP standard require written operating procedures. The regulators also require a phase within the procedures that is specific to emergency shutdown. The emergency shutdown procedures for a process must consider the following three:

- the conditions under which the procedure is applicable

- the assignment of shutdown responsibilities to qualified operators

- the shutdown is executed in a safe and timely manner

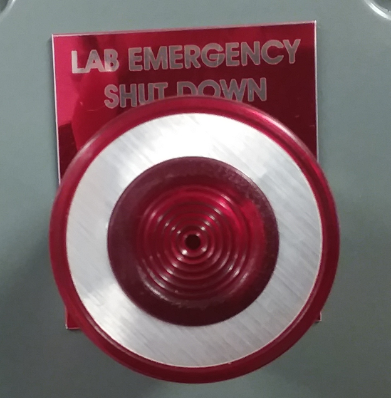

Leading RAGAGEP (best practices) would be IIAR and it is found in Standard 2. What is required at minimum for the E-stop when activated under this IIAR standard?

- Off only control for compressors

- Off only control for liquid pumps,

- Off only control for normally closed automatic valves within the machinery room.

Some questions to your PSM team from GCAP

- Has your training addressed who is and who is not qualified to perform an emergency shutdown?

- Can an active leak become worse by activating the E-stop if the leak is on the suction side of the system?

- Can an active leak become worse by activating the E-stop if the leak on the high side of the system?

- Do you need more than 1 switch if you have more than one common door to engine room?

- Can you get to the switch in an emergency situation?

- How often are the switches tested?

- After the switch is activated, what actually happens?

- After the switch is activated, what are the remaining, if any, electrical sources in the mechanical room?

- Does this switch disconnect power to the ammonia sensors?

- Does this switch disconnect power to the exhaust system?