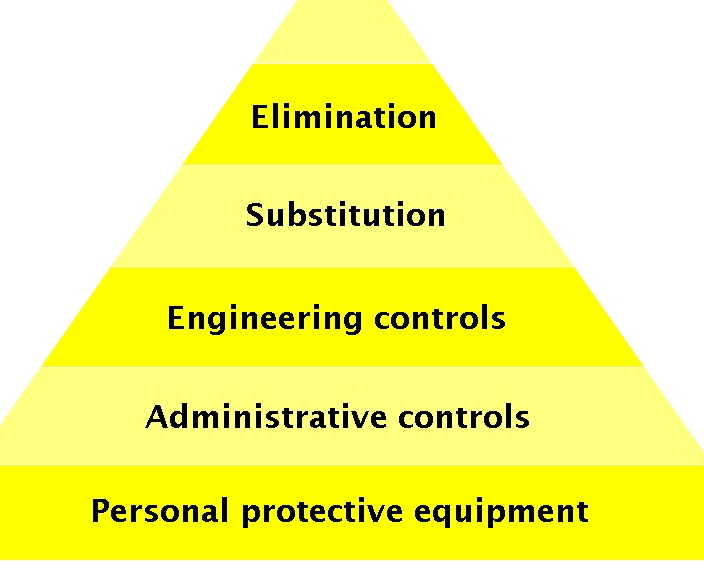

One of the most important tools in occupational health and safety is the hierarchy of controls. Unfortunately, it also is one of the least understood by the people who must make it work – employers and their employees. If you read texts on safety engineering, industrial hygiene, or similar topics, you will find a discussion of the hierarchy. But the details vary. For most, “engineering controls” represent the preferred solution to safety or health hazards. For others, particularly those dealing with chemical exposures, “substitution” of a less hazardous chemical is the highest control; others treat substitution as a form of engineering control.

Many chemical exposure rules reflect a hierarchy that places “administrative” or “work practice” controls on the same level as “engineering controls,” above “personal protective equipment” (PPE), the least preferred alternative.

This language can be confusing. I have heard safety professionals describe fall protection systems as “engineering controls” because they have to be “engineered.” But fall arrest and fall restraint are personal protective equipment, with all of PPE’s limitations.

And rules that equate “work practice” or “administrative” controls with engineering controls often lead people to mistakenly believe that training in safe individual work practices (however difficult those practices may be to follow) somehow eliminates the hazard.

With this confusion even among safety and health professionals, there is little wonder that many employers misunderstand the hierarchy and its value. They at times seem to believe that we prefer engineering controls simply because they cost more (which is often not true).

The basic principles behind the hierarchy are simple: A control that fully eliminates the hazard is better than one that does not, and controls that do not depend on individual employee behavior to work are better than controls that work only if precisely implemented by an employee.

The hierarchy reflects a recognition that human error will occur. If a control relies upon error-free performance, it will fail. Noise and respiratory hazards exist even when effective PPE is used. And interlocks on guards are better than the guard alone – even though they do not make the guard stronger or more effective when in place and properly used. Instead, they increase the likelihood that it will be in place and properly used.

The hierarchy does not really address the control’s effectiveness if everything works properly. Instead, the hierarchy improves the control’s reliability – by reducing the consequences of individual human error. Should an employee who fails to seal check his respirator suffer lung disease? Should an employee who doesn’t reinstall a guard lose her fingers? Or should employees who don’t put in earplugs lose their hearing? The hierarchy of controls recognizes that perfection in human performance cannot be attained. But it also recognizes that the price of failure should not be serious injury, illness, or death

This article was written by Michael Wood, Administrator at Oregon OSHA

Listen to podcast from Michael on this subject at this link.