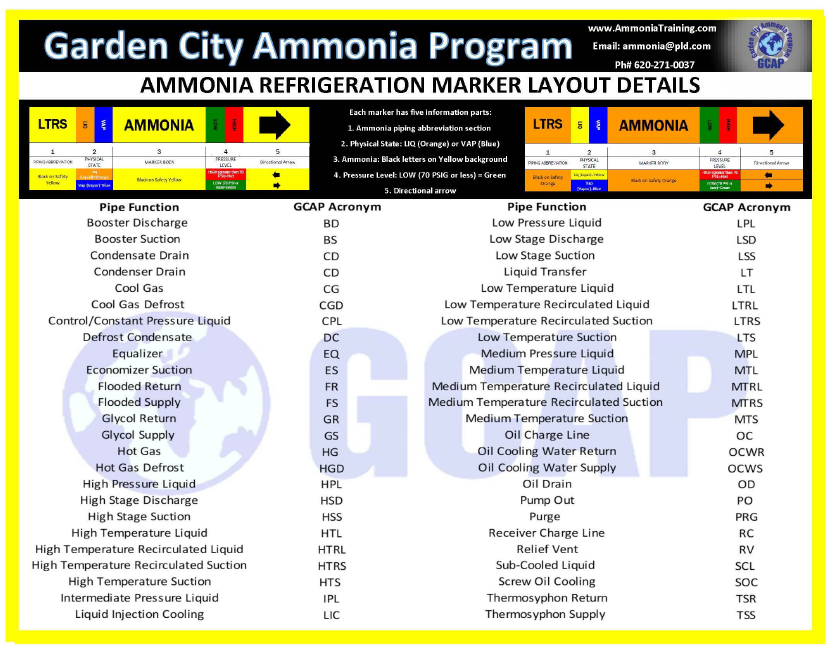

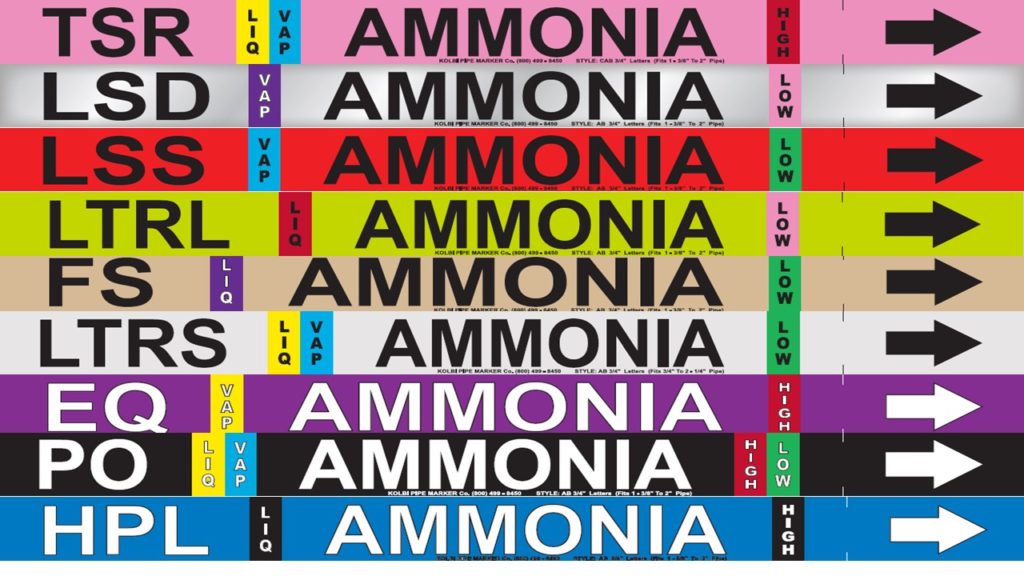

One of the best ways to learn your system is to find where all the major components of the cycle are located. After that is to see how they are connected with pipes. Each pipe used for a refrigeration purpose connecting these components should have labels identifying the purpose of the pipe, what state the refrigerant is in, direction of flow, and what pressure range it is in. Each name/acroynum of a label should be clearly defined and well understood by all involved within the system.

When you are learning your system it is not always easy to follow the pipes and can be quite intimidating. When a refrigeration system is properly labeled, it helps new and advanced operators understand what the pipes function is within the closed loop system. Correct labeling can also help in emergency situations. Labels are suggested located at the following places:

- Before and after a change in pipe direction

- Before and after piping penetrations of wall, ceilings, and floors

- On extended runs of pipe 4o’ between markers

- At least once in the area in which the pipe passes

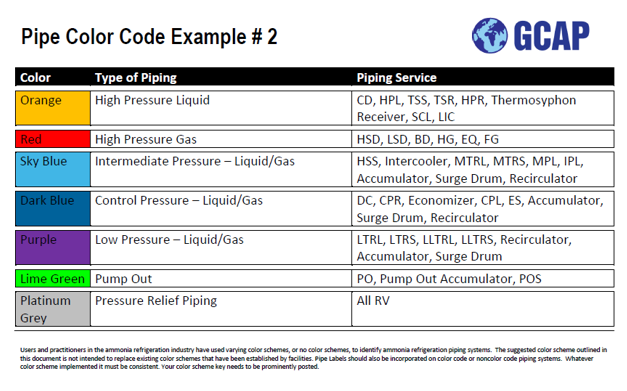

Has your company adopted a system specific color theme? Sometimes this color Theme will also include the insulated portion. What ever color scheme is used it must be identified, consistent, and well understood by all involved within the system.