Question from a past Student:

My company will not provide respirators or even think about a respiratory program.

Should I be actually working on the ammonia system?

Garden City Ammonia Program has some strong beliefs about air purifying full face respirators.

Every student that has been through any GCAP course will tell you that this level of PPE must be worn any time an ammonia refrigeration system is to be opened, including draining oil pots. Also a personal monitor of PPM of ammonia must be used when the APR is worn. GCAP will not stand behind the certifications/certificates of students through GCAP if they do not follow a couple of things back at their facility.

- Don on an ammonia rated respirator with monitor anytime the system is to be opened.

- Follow all operating/maintenance procedures for the process.

It is also a good practice in the ammonia industry to use a buddy system if the process is to be opened.

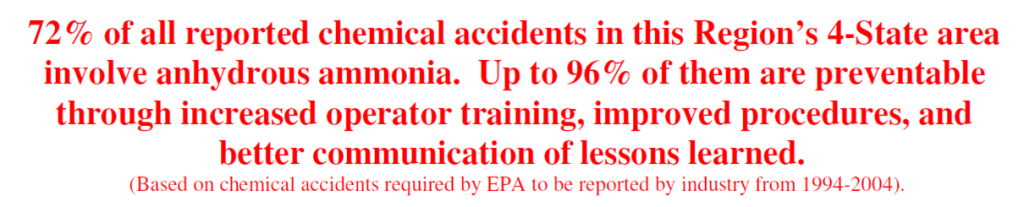

OSHA publicly stated in 2010 at the IIAR conference that over 80% of all related accidents with ammonia are involved in line openings such as draining an oil pot.

The following are some interesting facts: GCAP is not aware of any human loss of life to a person from ammonia when wearing a respirator. There may have been injuries, but no loss of life.

OSHA-170’s is a way to view accidents or deaths that involve a chemical such as ammonia. From the year 1984-2007 there was reported 208 incidents with ammonia and 84 deaths. Search OSHA-170’s

The US DOT has published that over 100,000 people have died in a 7 year time frame 2005-2012 driving on US highways. These two statistics are not directly related, but ammonia does has a safe tracking history considering how much of this chemical exists. In the United States there is 13,595,553,194 lb’s of ammonia in process that happen to have over 10,000 lbs requiring to follow PSM/RMP. This does not including the inventories of facilities that have less than the PSM/RMP threshold values. Check it for your self!

If a person chose to weld without a welding hood most experienced people would believe that person is insane. GCAP feels the same to any maintenance tech who chooses to open an ammonia system without wearing an air purifying respirator rated for ammonia.

GCAP’s discussion group on linkedin brought this up a few weeks back when one our students wanted the feedback from the audience but wanted to stay anonymous. This group is a private group and such great responses came out of it that I wanted to write this article. Please feel free to join the group to read all the responses, but here are a few:

- An absolute NO. Your company might need to have a chat with OSHA

- Purchase a bottle of ammonia, put a good quantity in a restroom, see how long they can stay in there without any protection, explain that this is not anything like anhydrous ammonia. I will bet it won’t be long before they come running out.. This is just crazy. Starting a respiratory program and purchasing the proper equipment is much cheaper than a willful violation.

- First and foremost, you should not work on an ammonia system without the proper PPE. Since your company refuses to have anything to do with a respiratory program, you should voluntarily manage your own PPE needs. Speak with the company safety personnel to explain the issues and educate them of their ignorance. Retracted Name has good points, especially alluding to hazard assessment, assuming the company has done such a thing. If they have and there is a PSM/RMP program in place, they definitely should know better.

- How about taking no for an answer, If your employer will not issue and train you in the use of respirators then your employer have no business having an Ammonia Refrigeration system in the first place

- First off, find a new company to work for. Once hired and you are ready to give your 2 week notice, schedule a meeting with the plant manager, safety manager and maint. manager. Then before the meeting, drain an oil pot, go to the meeting with the open pail of oil, and ask them if they would like to purchase the proper PPE NOW!!!! Sorry, this is a bad comment, but sometimes it’s the only way to make management understand.

Ammonia has been used in a compression refrigeration system for over 200 years. It will continue to be considered the best refrigerant known to man with one of the highest safety records. All personnel should be trained in the chemical(s) they will be working with and should become experts of that process. I would expect anybody that receives no gun safety training or instruction of how to use a gun will get hurt or even hurt or kill someone else. GCAP feels the same way about ammonia. Let’s put the ammonia in the hands of the right people who have been properly educated, supplied the proper tools/PPE, and given the opportunity to gain experience so they can do their job SAFELY.

Never Proceed Through an Ammonia Cloud!

[youtube width=”480″ height=”320″]http://www.youtube.com/watch?v=zvDEVhR7u4U[/youtube]

PPE PEL IDLH SCBA OSHA